How to re solder a wire without a soldering iron?

If you don’t have a soldering iron, you can use an old toothbrush to remove the old solder. Just hold the toothbrush to the joint, and when the solder melts, the toothbrush will gently push the melted solder out. If the connection is too tight, you may need to heat the joint with a small torch. Do not use a heat gun, as this could damage the plastic component.

How to repair a broken wire without soldering?

If your broken wire does not have enough solder on it, it will be extremely easy to break again. To fix a broken wire, it is important to add just enough solder to secure it to the broken end of the wire. Use a flat tip for applying the paste. This will give the paste an even coating. After adding the solder, place the tape over the wire so that the broken end is covered. Apply some pressure to the wire to make sure the solder is attached to the ends.

How to solder a wire without a soldering iron?

There are a few methods that can be used for resoldering wires. One of the easiest and most cost-effective is to use a solder sucker. Often times, these are found in the office supplies section of almost any store. These devices usually come with a plastic tube attached to the end that holds the solder. While the tube is one of the least expensive options available, it does require an investment on your part.

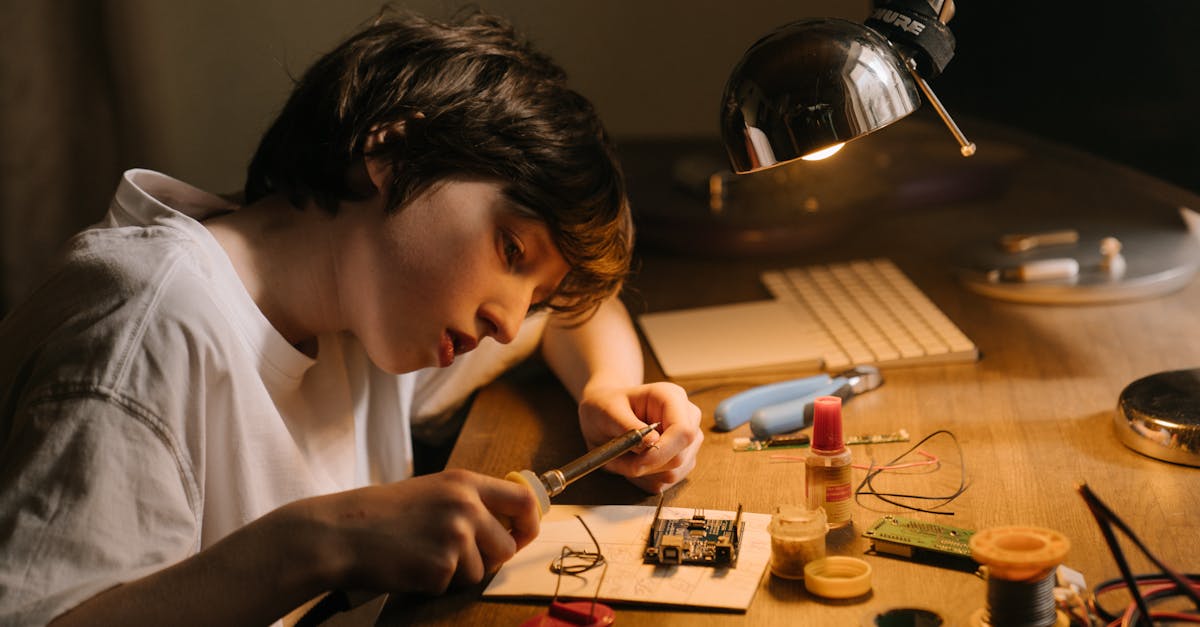

How to solder wire to a circuit board without a soldering iron?

It’s always best to use a high-quality solder and flux when soldering, but if you don’t have the right tools or don’t feel like you have the skill level, you can use a reworkable connector. Reworkable wire-to-board connectors come in a variety of styles and have a flat or round surface. Just apply some flux to the connector and the board, and the connector will easily attach and solder itself to the board.

How to solder a wire without soldering iron?

You might have heard that you can use a heated glass to melt solder and fix the connection of a broken wire. While it is true that you can do this, it is highly recommended that you do not use this method as the glass might damage your electronics. If you want to repair this type of connection, you need to use a special clamp that can be adjusted to the right temperature, making sure that the heat is enough to melt the solder but does not damage the wires.